Material Properties

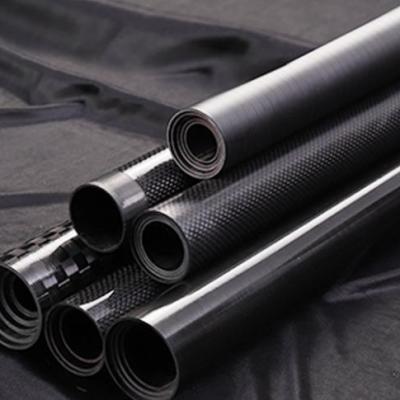

Carbon Fiber

Strength and Stiffness: Carbon fiber is renowned for its high strength-to-weight ratio and exceptional stiffness. It is significantly stronger and stiffer than fiberglass, which makes it ideal for applications where rigidity is critical, such as aerospace, automotive, and high-performance sporting goods.

Weight:One of the standout features of carbon fiber is its low weight. Carbon fiber tubing is lighter than fiberglass, making it the preferred choice in industries where weight savings are paramount, such as in aircraft and high-end bicycles.

Durability: Carbon fiber is highly resistant to fatigue and does not corrode. However, it can be more brittle than fiberglass and is prone to damage from sharp impacts or excessive flexing.

Fiberglass

Strength and Flexibility: While not as strong or stiff as carbon fiber, fiberglass still offers a respectable strength-to-weight ratio. It is more flexible and can absorb impacts better without cracking, which makes it a good choice for applications where some give is necessary, such as in certain types of sporting equipment and marine applications.

Weight: Fiberglass is heavier than carbon fiber but still lighter than many traditional materials like steel or aluminum. Its weight is usually not a critical drawback for applications where extreme lightness is not a requirement.

Durability: Fiberglass is highly resistant to corrosion and is less brittle than carbon fiber. It can endure rougher handling and impact, which makes it suitable for more demanding and varied environmental conditions.

Cost

Carbon Fiber: The superior properties of carbon fiber come at a price. Carbon fiber tubing is significantly more expensive than fiberglass. This higher cost can be a deciding factor for projects with tight budgets or where the high-performance characteristics of carbon fiber are not essential.

Fiberglass: Fiberglass is generally much more affordable than carbon fiber, making it an attractive option for many applications where budget constraints are a major consideration. Its lower cost does not mean it is inferior; it simply means it is more accessible for a broader range of uses.

Applications

Carbon Fiber: This material is chosen for high-performance and high-precision applications. Examples include aerospace components, high-end automotive parts, competitive sports equipment like racing bicycles and tennis rackets, and advanced engineering projects. The high strength, stiffness, and lightweight properties of carbon fiber make it ideal for these uses.

Fiberglass: Fiberglass is widely used in applications where cost-effectiveness and durability are key. This includes boat hulls, fishing rods, storage tanks, and architectural components. Its resistance to impact and corrosion makes it suitable for outdoor and marine environments.

In summary, both materials have their place in the world of tubing, each excelling in different scenarios. By carefully considering the specific needs of your project, you can choose the material that offers the best balance of performance, durability, and cost-effectiveness.