Carbon fiber and glass fiber tubes are both composite materials that are widely used in various industries for their unique properties. While they may look similar, there are significant differences between the two materials.

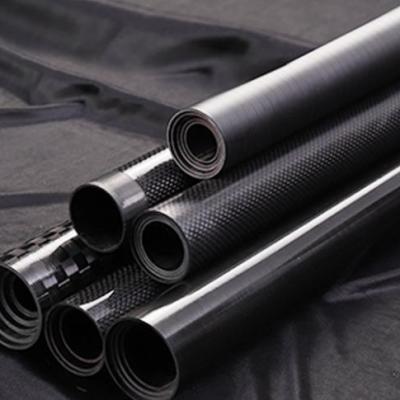

Carbon fiber tubes are made of carbon fibers that are woven or wound together and then bonded with a resin material. Carbon fiber tubes are known for their high strength, stiffness, and low weight, making them ideal for use in applications that require a strong and lightweight material. Carbon fiber tubes are also resistant to corrosion, fatigue, and high temperatures, which makes them suitable for use in harsh environments.

On the other hand, glass fiber tubes are made of glass fibers that are woven or wound together and then bonded with a resin material. Glass fiber tubes are less strong and stiff than carbon fiber tubes, but they are more affordable and have better impact resistance. Glass fiber tubes are also easier to work with and can be cut, drilled, and machined more easily than carbon fiber tubes.

Carbon fiber tubes and glass fiber tubes, also known as fiberglass tubes, are two different types of composite materials that are commonly used in a variety of applications. Here are some of the key differences between carbon fiber tubes and glass fiber tubes:

Material composition: Carbon fiber is made from carbon atoms that are bonded together in a crystal structure, while fiberglass is made from fine strands of glass that are woven together and bonded with a polymer resin.

Strength and stiffness: Carbon fiber is stronger and stiffer than fiberglass, which means it can withstand higher loads and stresses without deforming or breaking.

Weight: Carbon fiber is lighter than fiberglass, which can make it more suitable for applications where weight is a concern, such as aerospace or sporting equipment.

Conductivity: Carbon fiber is conductive, while fiberglass is non-conductive. This means that carbon fiber can conduct electricity, which may be a disadvantage in some applications where electrical conductivity needs to be avoided.

Cost: Carbon fiber is typically more expensive than fiberglass, which can make it less practical for some applications where cost is a significant factor.

Appearance: Carbon fiber has a distinctive weave pattern that is visible on the surface of the material, while fiberglass typically has a more uniform appearance.

Overall, both carbon fiber and glass fiber offer advantages and disadvantages depending on the specific application and requirements. Carbon fiber is typically used in applications where high strength, stiffness, and low weight are critical, such as aerospace, automotive, and sporting equipment. Glass fiber, on the other hand, is often used in applications where lower strength and stiffness are acceptable, such as construction, marine, and electrical applications.

Carbon fiber tubes are stronger, stiffer, and lighter than glass fiber tubes, while glass fiber tubes are more affordable and have better impact resistance. The choice between carbon fiber and glass fiber tubes will depend on the specific application and the requirements of the project.